Low-temperature storage tanks are designed to store cryogenic liquids at extremely low temperatures, ensuring their stability and preventing evaporation. These tanks are essential in various applications, including the storage of liquefied gases such as nitrogen, oxygen, and argon. The demand for low-temperature storage tanks is growing as industries increasingly rely on cryogenic technology for efficient storage and transport solutions. Manufacturers are focusing on developing advanced insulation materials and tank designs that enhance thermal efficiency and safety. As the market for cryogenic applications expands, low-temperature storage tanks are expected to play a critical role in meeting industry needs.

The cryogenic tank market has witnessed remarkable growth over the past few years, driven by the increasing demand for low-temperature storage solutions across various industries. Cryogenic tanks are specialized storage vessels designed to store gases and liquids at extremely low temperatures, often below -150°C. These tanks are essential for the safe handling of cryogenic substances such as liquid nitrogen, oxygen, argon, and natural gas. Their importance spans multiple sectors, including healthcare, food and beverage, energy, and chemicals, where maintaining the integrity of low-temperature substances is critical. The growing focus on industrial safety, environmental compliance, and technological advancement has fueled the need for cryogenic tanks globally.

Market Drivers

The primary factors propelling the cryogenic tank market include the increasing industrial use of liquefied gases, expansion of the energy sector, and rising demand for medical gases. In the healthcare sector, cryogenic tanks are widely used to store oxygen and nitrogen, which are vital for various medical procedures and emergency response situations. Additionally, the expansion of the chemical industry has led to an increased need for storing and transporting industrial gases safely. The energy sector, particularly in liquefied natural gas (LNG) storage and transportation, is another key driver of the market. With the world shifting towards cleaner energy sources, LNG has become a preferred alternative to traditional fossil fuels, further boosting the demand for efficient cryogenic storage solutions. Moreover, government regulations on safe storage and handling of hazardous gases have prompted industries to adopt advanced cryogenic tanks, enhancing both safety and operational efficiency.

Types of Cryogenic Tanks

Cryogenic tanks are available in various types, each tailored to meet specific storage and transportation needs. Stationary tanks are used for large-scale storage at industrial sites or power plants. These tanks are designed with high insulation capabilities to maintain extremely low temperatures for extended periods. On the other hand, mobile cryogenic tanks or trailers provide flexibility for transporting liquefied gases over long distances. They are widely used in industries where remote site delivery is required, such as construction, healthcare, and energy. Dewar flasks, another type of cryogenic tank, are smaller in size and ideal for laboratory or medical use. Each type of tank comes with its unique set of design features, insulation technologies, and safety mechanisms, contributing to the diversity and versatility of the cryogenic tank market.

Key Applications

The applications of cryogenic tanks are diverse, reflecting the wide range of industries that rely on low-temperature storage solutions. In the healthcare sector, they play a critical role in storing liquid oxygen for hospitals, clinics, and emergency care units. The food and beverage industry utilizes cryogenic tanks for preserving frozen foods, carbonated beverages, and liquid nitrogen-based freezing techniques. In the chemical industry, these tanks facilitate the safe storage and transport of industrial gases like argon, helium, and carbon dioxide, which are used in manufacturing, welding, and other industrial processes. The energy sector, particularly LNG, relies heavily on cryogenic tanks for storage and transportation. As the global energy landscape shifts toward cleaner fuels, the adoption of LNG and other cryogenic substances is expected to rise, further expanding the market.

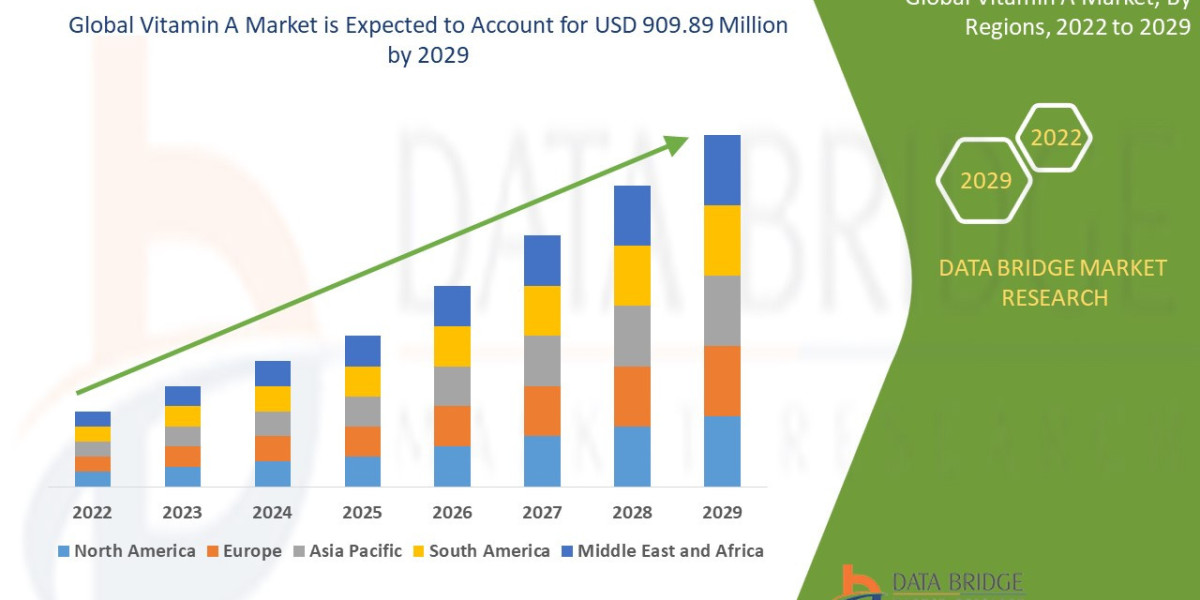

Regional Insights

The cryogenic tank market is geographically diverse, with strong growth observed in regions such as North America, Europe, and Asia-Pacific. North America holds a significant share due to the well-established industrial base, stringent safety regulations, and high adoption of advanced cryogenic technologies. Europe follows closely, driven by the focus on renewable energy and LNG storage infrastructure. The Asia-Pacific region is emerging as a high-growth market, fueled by rapid industrialization, expanding healthcare infrastructure, and increasing energy demands in countries like China and India. Additionally, the Middle East and Africa are witnessing steady growth due to investments in LNG infrastructure and industrial gas projects, presenting lucrative opportunities for market players.

Technological Advancements

Technological innovation is a key factor shaping the cryogenic tank market. Manufacturers are increasingly focusing on enhancing insulation materials, improving tank durability, and integrating digital monitoring systems. Advanced insulation techniques, such as vacuum-insulated panels, help maintain the ultra-low temperatures required for cryogenic storage, reducing energy consumption and operational costs. Digital sensors and IoT-enabled monitoring systems allow real-time tracking of tank temperature, pressure, and liquid levels, ensuring safety and efficiency. These technological advancements not only improve the performance and reliability of cryogenic tanks but also align with the growing industry emphasis on sustainability and operational excellence.

Market Challenges

Despite the promising growth, the cryogenic tank market faces several challenges. High initial investment costs, complex manufacturing processes, and stringent regulatory compliance requirements can hinder market expansion. Safety concerns associated with handling and transporting cryogenic substances require specialized training and strict adherence to operational protocols. Furthermore, fluctuations in raw material prices, particularly for high-grade stainless steel and insulation materials, can impact production costs. Market players must address these challenges through innovation, cost optimization, and strategic partnerships to remain competitive.

Future Outlook

The future of the cryogenic tank market looks promising, driven by increasing industrial applications, technological advancements, and global demand for cleaner energy sources. The growing adoption of LNG in power generation, transportation, and industrial processes is expected to create significant opportunities. Additionally, the healthcare and pharmaceutical sectors will continue to rely on cryogenic tanks for storing medical gases and biological samples. Market players focusing on innovation, digitalization, and sustainability are likely to gain a competitive edge. As the world moves toward industrial efficiency and energy transition, the cryogenic tank market is poised for steady growth and long-term success.

Conclusion

In conclusion, the cryogenic tank market represents a vital segment of industrial storage solutions, offering safety, efficiency, and technological sophistication. With increasing applications across healthcare, energy, chemical, and food industries, the demand for cryogenic tanks is set to grow steadily. Technological advancements, regional expansion, and the shift toward cleaner energy sources will continue to drive market growth. Despite challenges related to cost, safety, and regulations, the market’s long-term prospects remain strong, making cryogenic tanks an essential component of modern industrial infrastructure.

More Related Reports

Industrial Waste Management Market